Total Guide to CNC Jigs, Fixtures, and Workholding Solutions for Mills

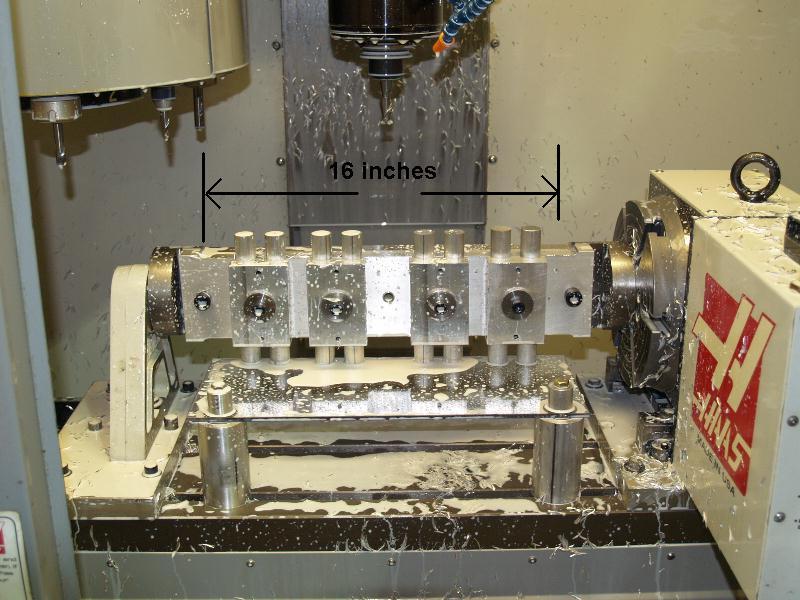

Workholding devices, when used correctly, enable the CNC machine to operate at its full capability to produce high-quality parts. A strong workholding method is important because of the following: Increased Part Immobility For high accuracy and precision, the entire cutting operation needs to be stable and immobile.

CNC Workholding Clamps & Machining Fixture Clamps & Devices

CNC Workholding Solutions From BIG DAISHOWA - Americas Products Tool Holders BIG-PLUS Spindle System Collet Chucks Milling Chucks Hydraulic Chucks Tapping Holders Basic Arbors Coolant Inducers Cutting Tools Indexable Cutting Tools Solid Carbide HSS Boring Tools Modular Components Rough Boring Heads Fine Boring Heads OD Turning Face Grooving

Workholding for CNC Manufacturing Resources Fast Radius

Our line of Kurt vises includes CNC vises, 5 axis vises, rotary table workholding solutions for VMC's and the ToolBlox tombstones, providing you with increased versatility at your machining stations. Precision measuring systems and accessories are also available to complement your Kurt workholding system.

to the future of CNC workholding. Innovative workholding solut Livetools

We are a world-class manufacturer of superior solutions for the metalworking industry. Mate manufactures workholding, CNC punch press tooling, and a comprehensive, superior line of press brake tooling. Mate Laser Technologies serves the CO2 and fiber laser market with premium quality optics, nozzles and accessories. Featured Event.

PAWS Workholding Workholding Solutions For CNC Milling

The trusted global leader in workholding fixture solutions for CNC machining centers and milling machines. As the original inventor of the wedge-operated Low-profile Clamp, OK-VISE® has been at the forefront of fixturing innovations for years. Our high-quality components and fixturing systems ensures a secure hold on the widest range of.

CNC Workholding Clamps & Machining Fixture Clamps & Devices

Increase your factory productivity with the 52/96 CNC workholding solutions from Mate Precision Technologies: Mate DynoGrip™ Vises, Mate DynoLock™ Bases and Mate DynoMount™ Mounting Accessories. Mate understands your CNC workholding challenges and we guarantee your satisfaction.

Workholding Solutions for HAAS CNC Mills Martin Trunnion Tables

CNC workholding refers to any device or apparatus used to keep a workpiece properly positioned and immobile during the machining process. Common examples are chucks, clamps, end stops, soft or hard jaws, locators, vises, fixtures and jigs. Workholding in a CNC machining process is a potential issue. If workpieces are hard to grasp or grasped.

Total Guide to CNC Jigs, Fixtures, and Workholding Solutions for Mills

In keeping with our philosophy of Breakthrough Engineering, Norgren is challenging traditional thinking about workholding solutions for CNC machining customers; actively exploring new ways to tackle some of the key operational issues the industry faces every day.

CNC Workholding 5th AXIS YouTube

Workholding Solutions and Workholding Fixtures. The Ahaus Workholding Department started in 1995, and we have built nearly 5,000 fixtures for the automotive, machine tool, valve, construction and other industries. We work with machine tool manufacturers, distributors, and users to meet specified requirements for positioning, placement, number.

Dillon Manufacturing Provides the Best Workholding Solutions Dillon Manufacturing

Workholding refers to any device used to securely position and firmly hold a workpiece in its proper orientation to the tooling with enough force to resist the forces of machining without deforming the part. The importance of proper workholding should not be underestimated.

Workholding Solutions PAWS Workholding

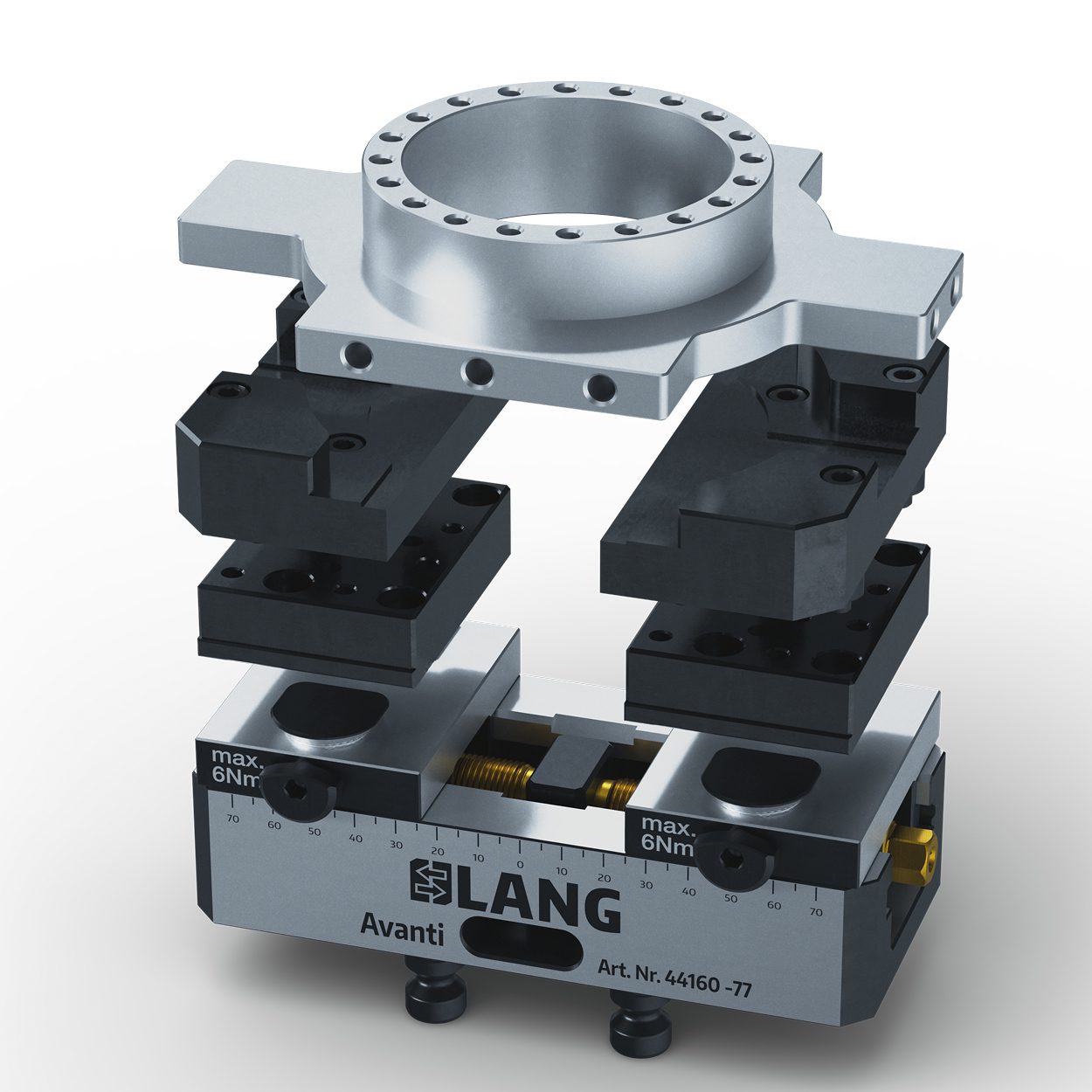

Workholding is a fundamental aspect of CNC machining that involves securing a workpiece in a fixed position and orientation during the machining process. It encompasses a variety of methods and devices used to hold, clamp, or fixture a workpiece, preventing movement or deformation during machining operations. The ultimate goal of workholding is.

Total Guide to CNC Jigs, Fixtures, and Workholding Solutions for Mills

To learn more about our vast offering of services, speak with our staff or start a free quote, get in touch with Precise Tool & Manufacturing today. Request a Quote. CALL: 585-247-0700. 3 Generations of Precise Tool & Manufacturing - Facility Tour 2022! See Precise Tool's Newest Work.

Total Guide to CNC Jigs, Fixtures, and Workholding Solutions for Mills

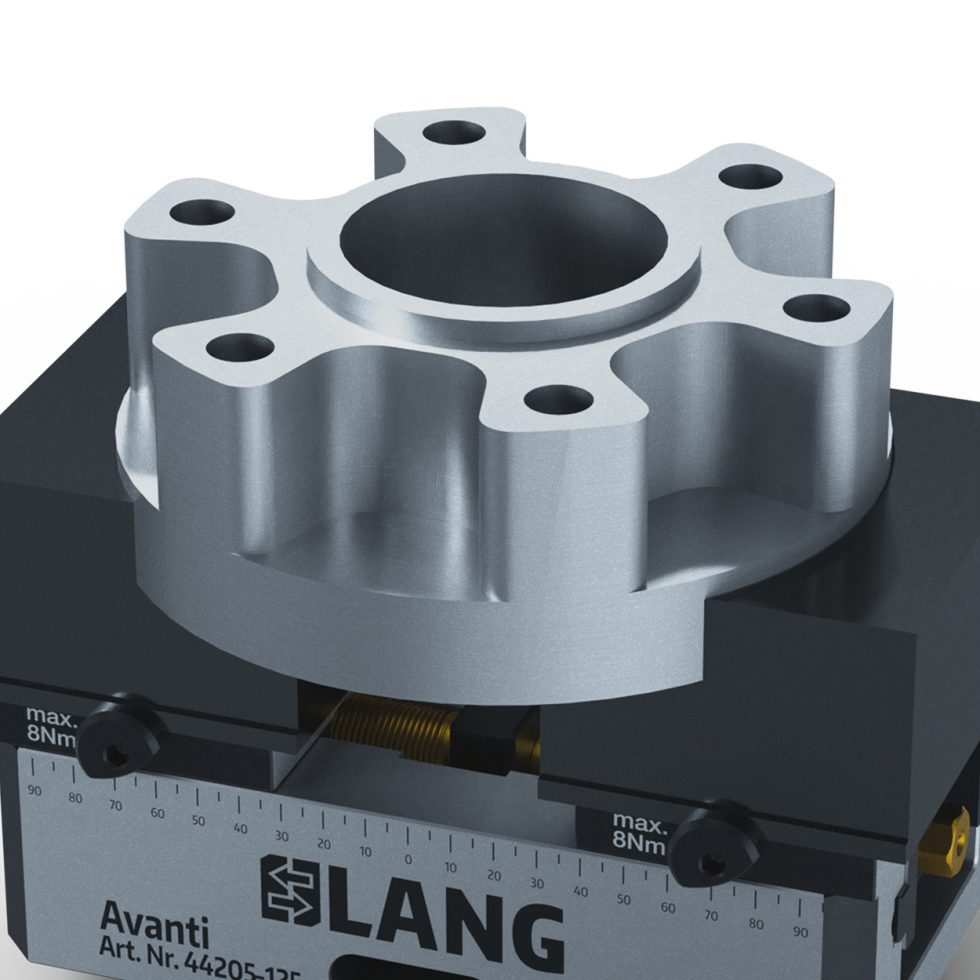

The choice of workholding solution can significantly impact the efficiency, precision, and safety of the CNC machining process. From traditional vises and clamps to more advanced fixture plates and soft jaws, the range of workholding solutions is vast and varied, each with unique advantages and applications.

5th Axis Workholding Solutions Akhurst Machinery LTD

With knowledge of the potential load, you can start narrowing down options for CNC workholding solutions. If you are machining a small brass part, you may be able to use a slightly less sturdy but also less invasive workholding method. With a large steel part, you'll want more substantial fixturing.

Standard or bespoke Hyfore and ETG Workholding have the full capability at MACH 2016

Workholding is the generic term for any device used to firmly hold your workpiece to the CNC machine while machining it. Closely related terms are "jigs" and "fixtures." A fixture holds your workpiece while it is being cut. A jig holds the workpiece and also guides the cutter.

Introduction to Workholding Options for CNC Machining Fictiv

The original Kurt AngLock® vises were designed to provide precision part clamping for basic machining and milling applications. Our line of Kurt vises includes high precision CNC vises, 5-axis vises, rotary table workholding solutions for VMCs, and ToolBlox tombstones. Our precision workholding solutions provide increased versatility at your.